CNC stands for “computer numerical control.” The CNC machines are electro-mechanical or hyper precision computer-controlled manufacturing devices.Did you know the CNC machine market will be over 100.9 billion by 2025 globally?

In fact, many industries are incorporating CNC machining into their manufacturing process to boos their production using CNC machines. These machines allow for a wider range of applications versus manually operated devices. A CNC machine allows for 3D cutting tasks to be accomplish in a single set of prompts. This means that it requires very little human intervention to operate, hence increasing production considerably.

What is CNC Machining?

CNC machining is the process of using computer-controlled machine tools to manufacture a part out of a solid raw material. CNC machines run on a pre-programmed computer software that controls the machinery in the production process. G-Code essentially controls all features like Feed rate, Coordination, Location, and Speeds. Once the codes are put into a CNC machine, it operates on its own. The machine tools, speed, and position of machinery are run through software.

CNC machines operate like robots. Therefore, they run faster with the highest precision and accuracy in order to transform a digital design into a physical part. These machines provide a level of accuracy, efficiency, and consistency that would be unachievable through a manual process.

CNC machining is use in several industries however it’s most prevalent in metal, plastic, and wood production. In fact, CNC machines are arguably the only way to produce high-precision metal parts for engineering designs across the world. Possibly, CNC machining is also the most significant manufacturing process of the 21st century as its functionality drives technological advancements across the globe.

How can businesses take advantage of the tax deductions available through this section of the IRS code?

The deduction is available for a wide range of business-related purchases, including software, office furniture, industrial machinery – even commercial heating and cooling units – as long as it’s used for business purposes more than 50% of the time. New or used equipment both qualify for the deduction. So do leased items, as long as you are the one making payment on the lease (i.e., not a sublease).

The maximum amount that can be deducted is $1,000,000. So if your business spends $2 million on eligible equipment purchases, only $1 million (the first million dollars) will qualify for the Section 179 Deduction. Also, keep in mind that the $1 million limit is reduced dollar-for-dollar if your eligible equipment purchases exceed $2.5 million in a single tax year. In other words, if your business buys $3 million worth of qualifying equipment, only $750,000 will be eligible for the special depreciation deduction (the first $2.5 million multiplied by 50%).

In years past, businesses could only deduct a small portion of their equipment costs each year through what’s called “depreciation.” Depreciation is used to spread out major capital expenditures over several years so that businesses don’t have to write off everything at once – but it doesn’t do them any good in the current year when they need it most! The advantage of taking advantage of Section 179 instead is that your business gets an immediate tax deduction for 100% of those significant capital expenditures in the current year when you need it!

Depreciation may still be the way to go for some businesses or certain financial situations. But for many companies, taking advantage of Section 179 can lead to substantial savings in the year that a qualifying product was purchased. That makes it advantageous to decide if now is the time to make that major purchase you’ve been thinking about.

What Are Different Types of CNC Machines?

With the advent of new technologies, the mechanisms of the pre-existing tools were improve initially with analog computers and eventually with digital computers, leading to a significant rise in CNC machining. There are different types of CNC machines that can produce different parts. Each machine differs in physical appearance owing to its construction and the way they operate and the type of parts it can make. In case you want to purchase a CNC machine for your business, you need to know the different functions of different machines.

However, there are various certified sellers and a marketplace where you can easily find CNC machines for sale. Even if you’re looking to buy a used CNC machine, you can have plenty of affordable options. It is important to note that CNC machines are not like any ordinary machines. They can only be operate by experts to produce high-quality products with precision.

Here we talk about a variety of CNC machines and each one of them caters to a specific purpose.

CNC Milling

CNC Mill is arguably one of the most commonly use types of CNC machines, a CNC mill utilizing computer controls to trip several workpieces. Mills can translate specific programs of numbers and letters in order to move the spindle in various ways.

Many mills use a written code what is known as G-code, which is a standard computer language understand by most CNC machines. A CNC mill can perform a variety of functions, which include face milling, drilling, coring, cutting gears, shoulder milling, tapping, turning, etc. You’ll find some CNC mills in three to six-axis configurations. A CNC mill is very large and can be quite expensive, however you can always rely on certified sellers where you can buy used CNC machines. There’re several CNC milling machine manufacturers such as HAAS, Okuma, & DMG Mori. Explore used CNC machines here.

CNC Lathe

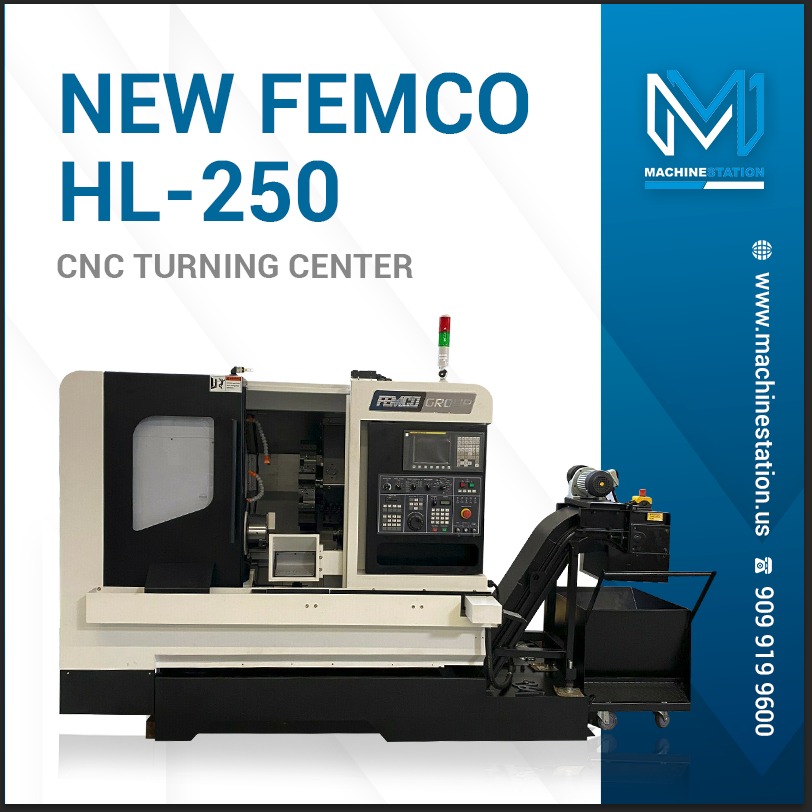

It is a CNC machine that operates to cut work pieces as they spin. CNC lathes use several tools to make accurate cuts with the highest precision. These machines also understand or read G-Code and can be use to make symmetrical objects such as spheres, cylinders or cones.

CNC lathes are effectively accurate compared to manual lathes. They usually have fewer axes than CNC milling machines, and are therefore compact and smaller in size. However the framework of these CNC machines are quite similar to the manual lathes. Some common CNC lathe manufacturers are Mori Seiki, Okuma, and HAAS.

CNC Router

A CNC router is a machine that is actually a type of CNC mill and similar to a handheld router used for cutting objects. The CNC router is mostly use to cut wood, plastic, foam, steel and aluminum. These machines cut down waste and boost productivity by manufacturing several products in much faster turnaround times than other machines. You can also find CNC routers in three to six-axis configuration.

CNC Plasma Cutters

These types of machines use a powerful plasma torch to cut various materials. CNC plasma cutters are commonly use to cut materials like steel and other forms of metal. As far as shape and size are concerned, CNC plasma cutters are quite similar to CNC routers. However, these CNC machines only work with two-dimensional configuration.

What Software Is Used in the CNC Machining Process?

Software is one of the most crucial parts when it comes to the CNC machinery.

CAD: It is a computer software that refers to Computer-aided design. It helps designers creating computer models defined by geometrical framework. This design software enables designers and draftsmen with the creation of surfaces; three-dimensional contours that determine the configuration and can then be use in CAM for the CNC machine process.

Some of the most popular CAD software includes SolidWorks, AutoCAD, Mastercam, and Rhino3D

CAM: CAM refers to Computer-aided manufacturing (CAM). CAD is a design software while CAM “reduces manpower costs” in the manufacturing process. Both CAD and CAM require powerful computers. Some of the most popular CAM software includes: Fusion 360, Solid Edge, SolidWorks CAM, and Mastercam.